a) Radiation heating (heat radiation-like the sun heats the earth) - direct radiation heat is stronger with large screens. In our climatic area, intense radiation is unfavorable, it dries out the dry air in winter anyway, lips crack, eyes blink, and it is especially unfavorable for solitary fireplaces, so we don't recommend them for continental climates by any chance;

b) Air heating - Our concept of air-heating fireplace is built as a robust, welded construction of elastic boiler steels (Ч.1202, Ч.1204), 5mm thick, double ribbed due to intensification of energy release (like radiators). Between the firebox and the insulated lining is an air heating chamber, where warm air naturally circulates and heats the room through the openings on the hood. Depending on the performance, these two types emit 6-10kW. 150-250W is needed per 1m2 of space. Fireclay fireplace does not have component B.

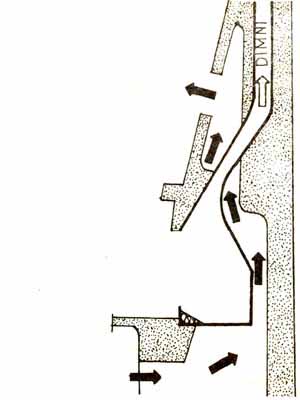

c) Boiler heating - Water, antifreeze or thermo-oil have incomparably higher energy absorption than air. The boiler fireplace is our standard product and we make it as a complementary component or basic unit to the classic radiator heating system. Depending on the energy requirements, it can be:

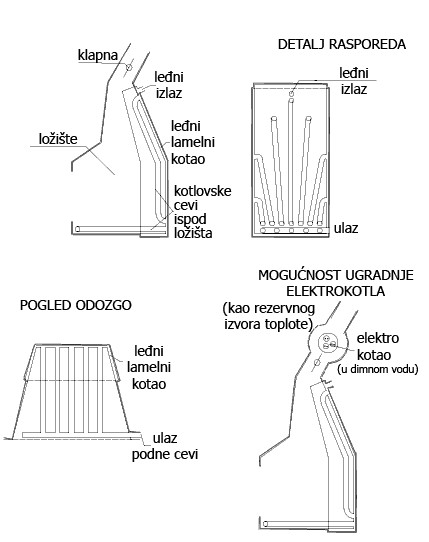

Panel boiler fireplace – The shell of the fireplace is ˝dressed˝ in a centimeter layer of water up to 8 liters. The boiler has a 5mm fire side and a 3.5mm air side, with water in between. As a rule, the fire side is ribbed.

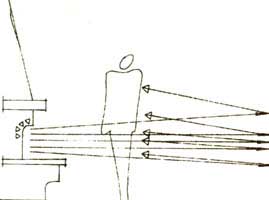

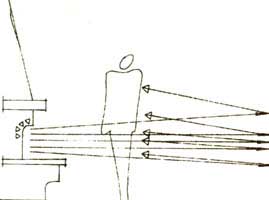

Tubular screen - On the fire side, in front of the panel finned boiler, a specially designed pipe network is made of seamless boiler pipes that are directly ˝immerged˝ in hot gases.

Electric boiler - We install an electric unit of 6, 12, 18 or 24 kW in the system, and the electric boiler itself is placed in the zone of hot gases, so it represents the third stage of the thermal boiler.

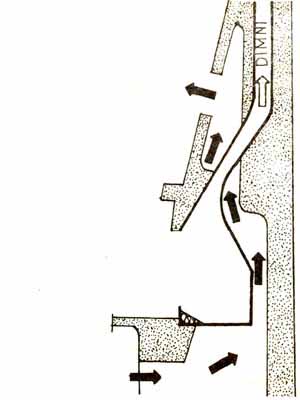

Preheater - In order to materially use the energy of hot combustion gases, we are making a preheater unit in the connecting segment between fireplace and chimney. According to the customer's request, the combination of the above elements results in: panel, double, triple and quadruple fireplaces.

The Institute for Chemistry, Technology and Metallurgy ˝, Belgrade, was hired to evaluate the thermal effects of our fireplace, whose instruments were used as authorized measuring units. The test showed that the dominant C component, i.e. the effect of the boiler fireplace in the variant: - triple boiler fireplace: panel, ribbed, tubular with electric boiler, proven power 38 kW.

To this should be added the first two types of heating A+B=4-6kW and the electrical unit of the requested power. According to the methodology of determining the nominal power, the test was carried out in ideal conditions - medium-sized dry wood (fast fire) and completely clean boiler surfaces. The real heat output is 70% of the nominal.

In this case, it is 38×0.7=26.6kW + 5kW =31.6kW, which is according to the norms, and largely depends on the thermal quality of the object. Optimal firebox screens from the energy aspect are 3500-4000cm2, i.e. 70-75cm wide, 48-55cm high, which corresponds to a 25×25cm or Ø 30 round section chimney.

The mentioned fireplace covers 100-140m2 of a residential building where the installed unit represents a backup or alternative system.

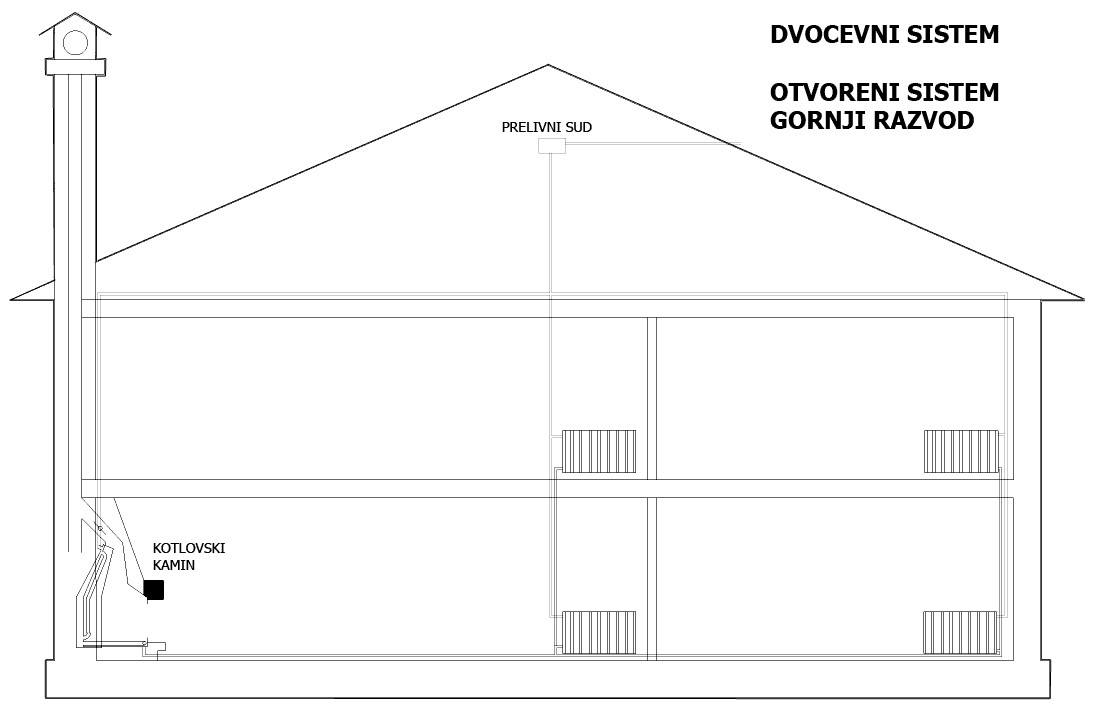

Inclusion of the boiler fireplace in the central heating system

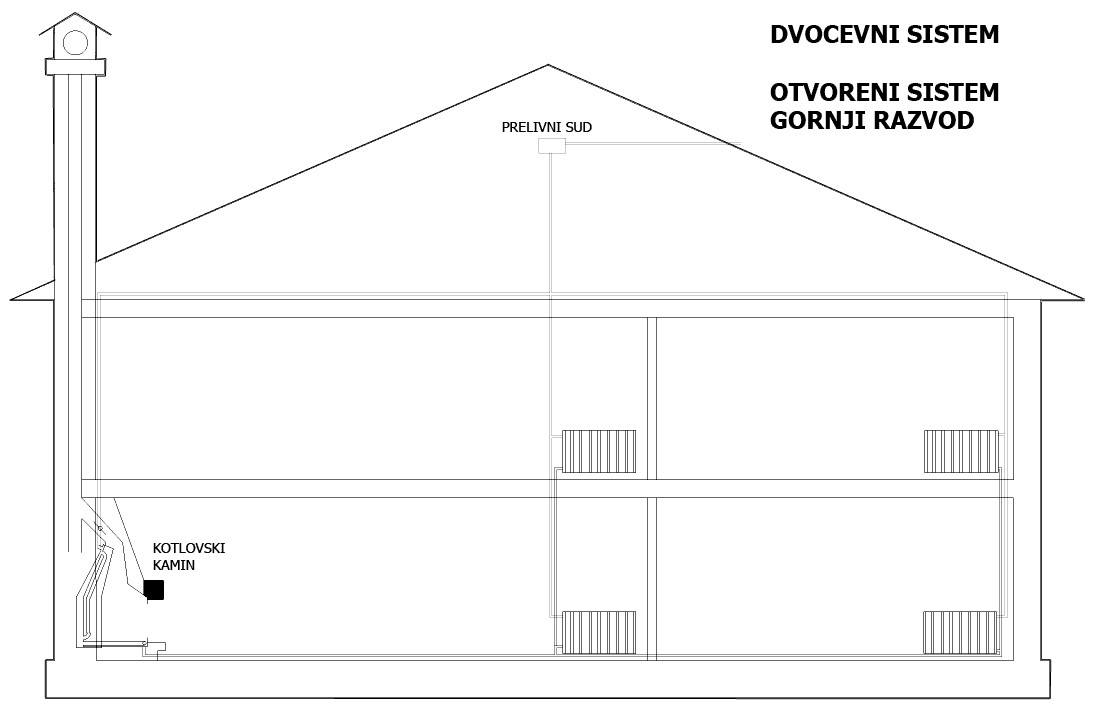

A boiler fireplace can be a basic or supplementary unit. It can be combined with a gas, liquid or coal boiler. In relation to the mentioned boilers, the fireplace has the disadvantage that it is more difficult to regulate the combustion speed, and thus the energy value. In combined systems, we always install the fireplace as a pre-heating unit. In order, the return line (ZURICKCHLAG) goes to the pump, the fireplace, some of the other units - the network. As a rule, we do not perform heating networks, but we provide detailed instructions or a project with a recommendation for the construction team. As for the heating system, we always give preference to:

- two-barrel versus single-barrel system

- open versus closed system

- upper in relation to the lower distribution of the network

- cold water pump

All this results in minimal problems in exploitation.

System protection

For twenty years, the following company for the production of distribution equipment and radiator networks in the area of Belgrade and its surroundings is "Ferad" Belgrade, Cerovina Miloje. Overheating of the system has never happened, due to air plugs, faulty expansion vessel and steam in the pump.

In dozens of examples when the investor has conditioned his network contractor, I have come across painful situations when the master-installer, while respecting his skills, opposed our concept. A well-intentioned investor, pressed by professional terms - buoyancy, submerged radiators, cavitation, looks at me or the installer in confusion, and probably cursing the moment he decided to build a boiler fireplace.

The professional discussion is spiced up by the vain installer, under the template dogma, with the sentence "you installed a bomb in people's house". Along these lines, every facility is equipped with a series of bombs in the form of boilers, steam irons, pressure cookers... If we ask a person who is forced to be in water: Would he rather have his head under water or above it? Would you rather take air from the atmosphere or from an expansion vessel?

Autumn 2011, two boilers with burnt heaters. Professional expertise - electric heaters burst like a sausage in hot oil. AIR IN THE ELECTRIC BOILER!

Famous investor quote: I know it's not your fault, but please replace the heaters...